PLUM

Fixed Type Flexo Printer PLUM

Always pursuing high quality, stability and operability

Instead of simply pursuing high-performance equipment that we can be proud of, we focus on truly reflecting the needs of customers on the equipment. This is the performance of UMETANI machine. While developing for a variety of machine applications, our team leads the industry by producing excellent equipment with high quality, stability and operability.

Considering the balance between equipment performance and environmental protection

From the perspective of environmental protection, to reduce power consumption, reduce noise and vibration and safety operation, EQOS series has been considering the balance of all aspects and has been evolving to this day.

Of course, it is still evolving. EQOS series has always been designed based on environmental protection to reduce CO2 emission. As an excellent equipment for safety and environmental protection, EQOS series pursues the comprehensive balance performance of man machine interface and ecology, and is active in global market.

Each Unit of Equipment

Feeding Unit

Through the separate servo drive of 4 rows of conveying rubber wheels, control and eliminate the problem of idling and slipping.

The brush for removing paper powder is installed at the exit of feeding unit.

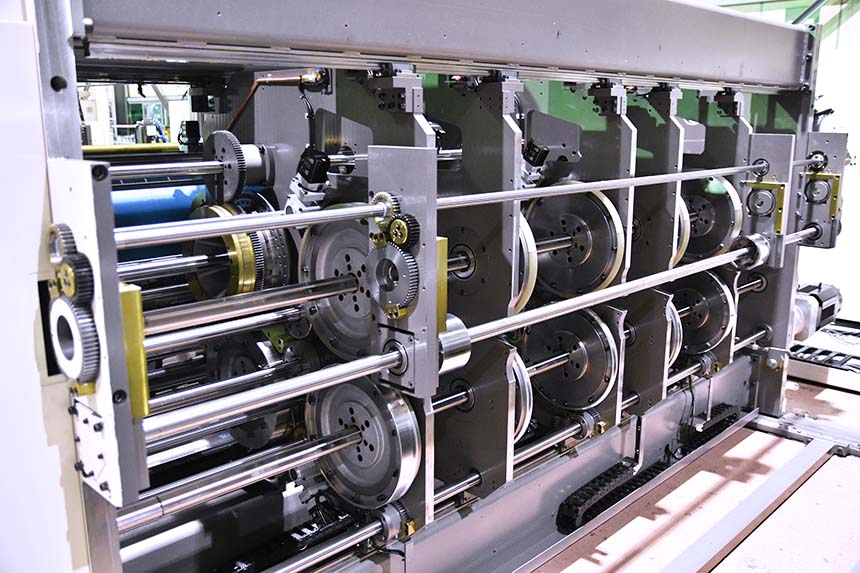

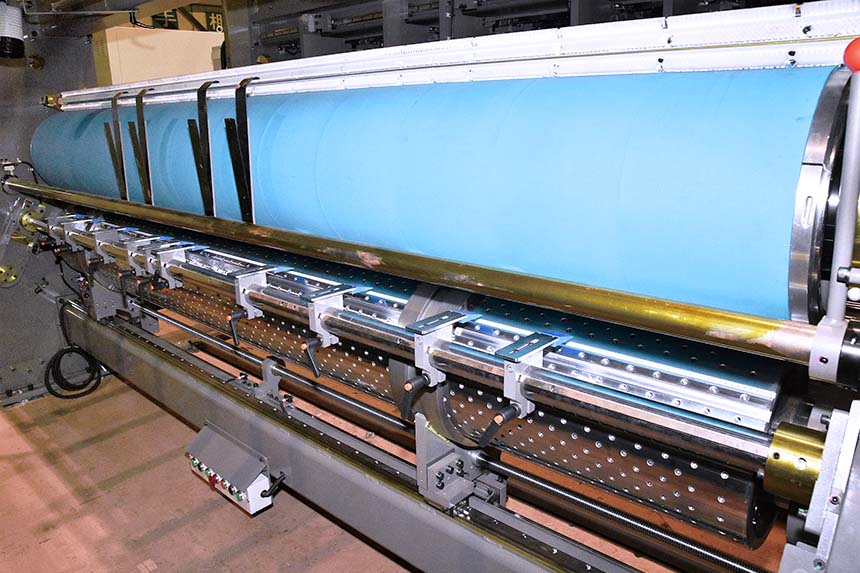

Printing Unit

Equipped with the ink chamber and ink circulation supply system independently developed by UMETANI.

Paperboard conveying is a vacuum adsorption specification with comprehensive rollers without transferring wheels and gap adjustment device.

Creasing Unit

By stabilizing the moving plate of the upper and lower line creasing on the crossbeam steel structure, higher precision line creasing is realized.

Slotting Unit 1

Install the line creasing wheel and slotting knife on the moving plate without shims for gap adjustment. Through the principle of separate up and down servo drive, it can realize automatic positioning more quickly and accurately.

Slotting Unit 2

Miniaturizing and optimizing the drive shaft, it improves the problem of paper scraps accumulation and makes the equipment maintenance easier.

Die-cutting Unit

The wood mold is equipped on die-cutting roller which adopts semi-automatic thimble specification.

Equipped with a circumferential speed balance specification without rubber grinding.